Are you trying to develop a new beverage brand and need help from a beverage research & development specialist?

Power Brands is the global leader in Beverage R&D — from concept to commercialization.

With decades of experience and thousands of successful beverage formulas developed for brands worldwide, our team of scientists, formulators, and innovators bring your vision to life.

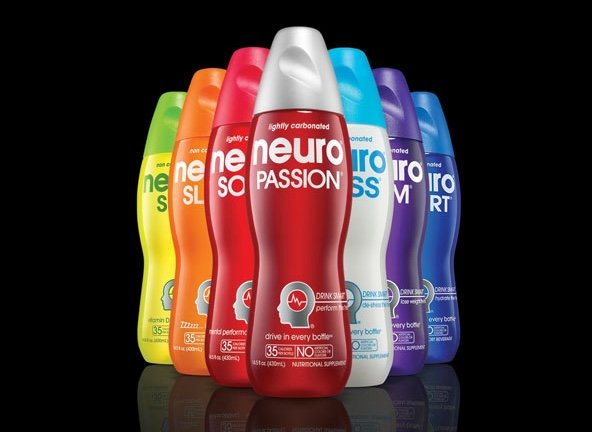

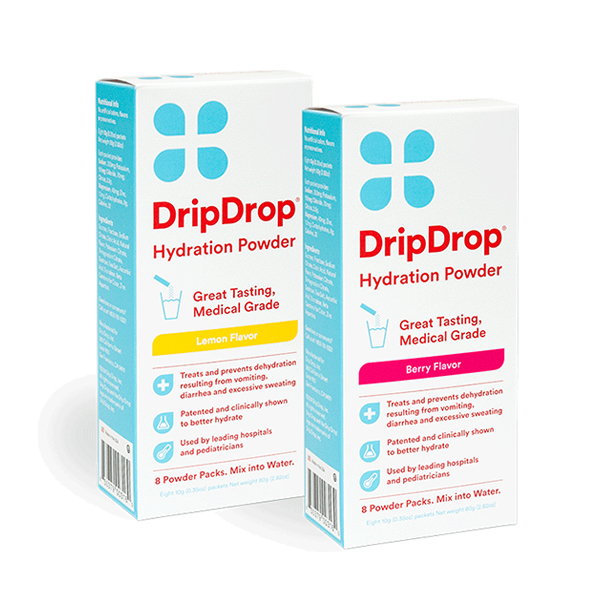

Trusted by Global Brands & Start Up Companies

Building Blocks of The Beverage R&D Process

Developing a successful beverage requires a strategic and well-executed beverage research and development (R&D) process. From initial concept ideation to full-scale production, every step must be carefully planned and executed to ensure product viability, market appeal, and regulatory compliance. A well-structured beverage R&D process encompasses several key components, including formulation, ingredient sourcing, sensory testing, packaging design, and commercialization.

At Power Brands, we specialize in guiding entrepreneurs and established businesses through every stage of the beverage research and development process. Whether you’re creating a functional energy drink, a plant-based protein shake, or a new hydration beverage, understanding the core pillars of beverage R&D is essential for success.

1. Concept Development & Market Research

The first step in any beverage research and development process is defining your brand’s vision, target audience, and unique selling proposition. This involves conducting in-depth market research to analyze industry trends, identify consumer preferences, and evaluate the competitive landscape. Understanding your audience’s needs helps determine the product’s flavor profile, functional benefits, and positioning.

2. Ingredient Selection & Sourcing

A strong beverage R&D process requires sourcing high-quality ingredients that align with your product’s functional and nutritional goals. Whether it’s natural sweeteners, organic flavors, or scientifically backed functional ingredients like adaptogens or electrolytes, selecting the right ingredients plays a crucial role in taste, shelf stability, and regulatory approval.

3. Beverage Formulation & Product Development

Once the ingredients are selected, expert food scientists and formulators work on developing the precise recipe to achieve the desired taste, texture, and functionality. The formulation process must account for factors like pH balance, solubility, preservation, and regulatory compliance. This stage may require multiple iterations to perfect the final product.

4. Sensory Testing & Consumer Validation

A critical aspect of beverage research and development is consumer testing. Sensory evaluation ensures the beverage meets taste and texture expectations, while focus groups and in-market tests provide feedback on consumer perception. Iterating based on this feedback helps refine the product before mass production.

5. Regulatory & Compliance Review

Every beverage must comply with FDA regulations and other industry standards for labeling, claims, and ingredient safety. Ensuring your product meets these guidelines is a crucial part of the beverage R&D process, as failing to do so can lead to legal challenges and market rejections.

6. Beverage Packaging Design & Testing

Packaging plays a vital role in brand identity and product success. An effective beverage research and development strategy includes selecting the right bottle, can, or pouch material, designing compelling branding, and ensuring functionality such as shelf stability and protection against light or oxygen exposure.

7. Pilot Production & Manufacturing Scale-Up

Before launching at full scale, a pilot production run helps test the manufacturing process, assess quality control, and determine potential production challenges. A seamless transition from beverage R&D to large-scale production is key to maintaining consistency and meeting consumer demand.

8. Commercialization & Market Entry Strategy

The final step in beverage research and development is preparing for market entry. This includes distribution planning, retail partnerships, and marketing strategies. Understanding pricing, promotion, and sales channels ensures a successful product launch.

Partner with Power Brands for Expert Beverage R&D

At Power Brands, we provide end-to-end beverage R&D services, helping brands navigate every stage of the beverage research and development process. From ideation to store shelves, our expertise in formulation, packaging, and manufacturing ensures your beverage stands out in the competitive market. Let’s bring your vision to life!

Develop Beverage with Power Brands Experts

At Power Brands, our highly experienced team of beverage scientists specializes in transforming innovative beverage ideas into commercial-grade formulations that are ready for mass production. Whether you're starting with a simple kitchen recipe or an early-stage concept, our experts ensure that your vision is not only preserved but also optimized for large-scale production without compromising quality, taste, or functionality.

Our beverage R&D team works meticulously to refine and enhance your formulation, ensuring it meets industry standards for stability, consistency, and consumer appeal. We take into account key factors such as ingredient interactions, pH balance, shelf life, and regulatory compliance, so your product is both market-ready and scalable.

By leveraging advanced formulation techniques and our deep understanding of the beverage industry, we help you create a successful, high-quality beverage that maintains the essence of your original recipe while being cost-effective and manufacturable at scale.

Work With Power Brands’ Beverage Experts Today

Our friendly beverage development specialists are ready to discuss how we can bring your idea to life and guide you through our proven R&D and commercialization process. Contact us today to learn more about our industry-leading beverage formulation services.

The Importance of Research & Development in Beverage Innovation

Research and development (R&D) plays a crucial role in creating a successful new beverage brand. In an industry where technology and consumer preferences are constantly evolving, staying ahead of trends is essential. A deep understanding of customer preferences, competitor innovations, and emerging ingredients is key to developing a product that stands out in the competitive beverage market.

At Power Brands, our R&D team is dedicated to staying at the forefront of industry trends and technological advancements. We continuously explore new ingredients, cutting-edge formulations, and market innovations to help create beverages that captivate consumers and outperform the competition.

Partner with Power Brands for Expert Beverage R&D

Our industry-leading R&D department ensures your beverage is not only innovative but also marketable and scalable. Let us help you develop a product that sets new standards in the industry.

-

Research and development (R&D) plays a crucial role in creating a successful new beverage brand. In an industry where technology and consumer preferences are constantly evolving, staying ahead of trends is essential. A deep understanding of customer preferences, competitor innovations, and emerging ingredients is key to developing a product that stands out in the competitive beverage market.

At Power Brands, our R&D team is dedicated to staying at the forefront of industry trends and technological advancements. We continuously explore new ingredients, cutting-edge formulations, and market innovations to help create beverages that captivate consumers and outperform the competition.

Partner with Power Brands for Expert Beverage R&D. Our industry-leading R&D department ensures your beverage is not only innovative but also marketable and scalable. Let us help you develop a product that sets new standards in the industry.

Executive Summary

Beverage research and development is the systematic process of transforming a market opportunity into a validated, scalable, and compliant product that delights consumers and sustains a brand’s commercial goals. It is a multidisciplinary effort that blends food science, sensory science, regulatory expertise, packaging engineering, manufacturing process design, and brand strategy. When executed well, R&D reduces risk, accelerates speed to market, safeguards quality, and creates long‑term competitive advantage through repeatable scientific methods. Treating R&D as a strategic capability—rather than a series of disconnected tasks—allows teams to convert insight into shelf‑ready products with fewer iterations, lower costs, and stronger consumer outcomes. At its best, beverage R&D is a learning engine for the business: each project builds knowledge that compounds across future launches, line extensions, and reformulations. Power Brands brings this integrated philosophy to every engagement, aligning scientific rigor with brand vision and commercial realities so that innovation is both inspired and operationally feasible.

Table of Contents

What Beverage R&D Actually Includes

Why R&D Matters for Competitive Advantage

Consumer Insight and Trend Intelligence

Ingredient Science and Formulation Strategy

Sensory Science and Iteration

Prototype Development and Rapid Learning Cycles

Processing Technologies and Their Implications

Packaging Design and Engineering for Beverages

Shelf‑Life Modeling and Stability Testing

Nutrition, Labeling, Claims, and Regulatory Pathways

Quality by Design (QbD), Scale‑Up, and Manufacturing Transfer

Costing, Sourcing, and Supply Chain Readiness

Sustainability and Responsible Design

Digital R&D, Data Systems, and AI‑Assisted Formulation

Stage‑Gate Governance and Project Management

Category‑Specific Considerations

Globalization, Localization, and Cultural Fit

Common Pitfalls and How to Avoid Them

Illustrative Mini Case Studies

Glossary of Beverage R&D Terms

Comprehensive FAQ

How Power Brands Partners with Founders and Operators

Readiness Checklist and Templates

Conclusion and Call to Action

1. What Beverage R&D Actually Includes

Beverage R&D spans far more than selecting flavors and mixing ingredients. It begins with a validated market need and ends only when a product can be produced repeatably at scale, delivered through the right package, and supported by accurate labeling and robust quality systems. The process typically includes market analysis; concept framing; formulation design; sensory optimization; pilot trials; processing selection; packaging engineering; shelf‑life modeling; regulatory review; claims and labeling; factory trials; and post‑launch learning. Each stage informs the next, and decisions are documented so that the product’s “why” is as clear as the “what,” enabling efficient iteration and reliable transfer to manufacturing.

At Power Brands, the R&D function integrates with brand strategy and operations from day one. Our scientists design for manufacturability while our commercialization experts plan for distribution realities such as temperature control, shelf allocation, freight constraints, and retailer expectations. This integrated approach keeps creativity grounded in commercial feasibility and regulatory compliance.

2. Why R&D Matters for Competitive Advantage

Effective R&D compresses the timeline between insight and shelf presence while protecting product integrity. Brands that invest in a robust R&D system benefit from reduced reformulation costs, fewer recalls, faster retail acceptance, and improved consumer loyalty. By defining target consumer segments, sensory objectives, claims strategies, and cost targets up front, the team avoids guesswork and repetitive cycles. Strategic R&D also future‑proofs a portfolio by building a library of validated formulas, ingredient specifications, and process templates that can be recombined to create new products quickly, without reinventing the fundamentals.

Power Brands has created thousands of beverage formulas for companies around the world, and those learnings translate into faster, smarter decisions. We apply proven templates for energy drinks, functional waters, teas, coffees, juices, performance hydration, and emerging categories, tailoring each to the brand’s positioning and regulatory framework. The result is innovation that is distinctive yet manufacturable, premium yet cost‑controlled, and novel yet safe.

3. Consumer Insight and Trend Intelligence

True innovation begins with understanding people—what they need, what they value, and how they make choices in context. Beverage R&D therefore starts with layered consumer insight. We blend syndicated data with qualitative discovery, social listening, in‑store observation, and rapid concept testing. We identify jobs‑to‑be‑done (e.g., sustained energy, mental clarity, hydration, gut comfort, indulgent treat, social ritual) and translate them into sensory and functional targets. We then map trends across taste, wellness, sustainability, and convenience, noting which signals are enduring and which are transient. This triangulation avoids chasing fads while still capturing fresh opportunities that resonate with real usage occasions.

Translating insight into design requires specificity. A “focus and clarity” claim may suggest a caffeine target, pairing with L‑theanine for smoother perception; a “calm and unwind” brief may require low‑calorie sweetness, chamomile or lemon balm notes, and warm flavor cues; a “performance hydration” profile implies an optimized electrolyte blend, osmolality tuning, and an isotonic or hypotonic strategy. We codify these linkages in design briefs so that formulation decisions tie directly to consumer promises and claims language.

4. Ingredient Science and Formulation Strategy

Ingredient selection determines sensory character, regulatory options, nutrition panel structure, cost, and process stability. Beverage developers balance sweeteners (sucrose, stevia glycosides, monk fruit, allulose, sugar alcohols), acids (citric, malic, phosphoric), buffers, flavors (natural, natural‑and‑artificial), colorants, emulsifiers, hydrocolloids (pectin, xanthan, gellan), preservatives (potassium sorbate, sodium benzoate, natural alternatives), and functional actives (caffeine, electrolytes, vitamins, adaptogens, nootropics) within the constraints of the intended process and package. Each choice carries trade‑offs in taste, clarity, cost, and label perception that must be weighed against the product promise and competitive set.

A robust formulation strategy defines target BRIX, pH, titratable acidity, osmolality, carbonation volume if applicable, and thermal or pressure treatment windows. Developers consider ingredient forms—liquid, powder, microencapsulated, emulsified—and their supply chain implications. For clean label objectives, we favor minimal additive systems while still achieving microbial safety and shelf stability. For premium functionality, we evaluate bioavailability, organoleptic impact, and claim substantiation pathways to ensure responsible, accurate communication.

Power Brands engineers formulas to meet the intended process—hot‑fill, tunnel pasteurization, cold‑fill carbonated, aseptic, retort, or high pressure processing (HPP)—and the intended package—aluminum can, glass, PET, HDPE, or multilayer cartons. We plan for line constraints like minimum fill temperatures, hold times, shear exposure, and dissolved oxygen targets, ensuring the lab formula becomes the line‑ready formula.

5. Sensory Science and Iteration

Taste is the primary driver of repeat purchase, and structured sensory science converts subjective opinions into actionable data. We use difference testing (triangle, duo‑trio), descriptive analysis to map attribute intensities, and hedonic testing to assess liking across target demographics. Calibrated panels generate sensory maps, while consumer tests identify preference drivers and “must‑have” cues. We combine this with online research to detect descriptive language consumers naturally use—words like bright, smooth, crisp, refreshing, creamy—to inform flavor naming and claims narratives.

Iteration follows a disciplined plan: adjust one variable at a time, establish guardrails for sweetness and acidity, and document the impact on aroma, mouthfeel, aftertaste, and flavor release over time. We incorporate temperature and carbonation effects, given that serving condition changes perceived sweetness and acidity. For functional products, we track bitterness, astringency, and herbal notes from actives and use pairing strategies—sweetness modulators, flavor maskers, texture modifiers—to harmonize the profile.

6. Prototype Development and Rapid Learning Cycles

Speed matters. Rapid prototyping shortens feedback loops and reduces waste. We set up weekly or even daily sprints where the team tests hypotheses, gathers data, and decides whether to scale, pivot, or shelve. Each iteration is logged with exact weights, processing conditions, and panel feedback to build a searchable knowledge base. Over time, the library becomes a strategic asset that accelerates future projects.

Power Brands leverages standardized base systems for common needs—electrolyte matrices, acidity buffers, natural flavor families, sparkling and still variants—allowing faster customization per brand DNA. With thousands of formulas behind us, we know the likely failure points and how to bypass them without compromising creativity.

7. Processing Technologies and Their Implications

Processing is not an afterthought; it is integral to product design. Hot‑fill requires low pH and heat‑tolerant flavors; tunnel pasteurization needs precise thermal penetration and closure integrity; cold‑fill carbonated demands tight microbiological controls and CO₂ management; aseptic requires validated sterilization and low particulates; retort suits robust products but can stress delicate flavors; HPP delivers fresh‑like quality for certain refrigerated products. Each method dictates ingredient choices, flavor selection, and packaging risks that must be addressed early in development.

We run process compatibility assessments early, modeling how acids, sweeteners, flavors, and functional actives respond to the specific thermal or pressure load. We plan for shelf‑life under realistic distribution scenarios—ambient, refrigerated, or mixed; light exposure; vibration; and thermal cycling. The goal is to ensure that the beverage consumers buy at month twelve tastes as good as the one sampled in month one.

8. Packaging Design and Engineering for Beverages

Packaging is a performance system. It protects quality, conveys brand identity, and influences usage occasions. We choose package formats based on distribution temperature, light sensitivity, oxygen sensitivity, carbonation, and sustainability goals. Aluminum cans offer strong light and oxygen barriers and are ideal for carbonated and nitrogen‑dosed products; glass conveys premium cues and thermal resilience; PET and HDPE provide weight and cost advantages with appropriate barrier layers; multilayer cartons and bag‑in‑box formats support foodservice and concentrated products. Closures, liners, and secondary packaging are specified to maintain integrity under real‑world conditions.

Power Brands pairs packaging engineering with design strategy. Our packaging team collaborates with formulators so the color palette, typography, and claims hierarchy align with the expected sensory experience and category cues. The result is packaging that looks beautiful, runs efficiently, and preserves flavor integrity across the product’s life.

9. Shelf‑Life Modeling and Stability Testing

Shelf‑life is the predicted period during which a product retains the desired quality under specified conditions. We design stability programs that monitor chemical, physical, and microbiological endpoints. Chemical markers include flavor volatiles, vitamin retention, non‑enzymatic browning, and lipid oxidation; physical markers include phase separation, sedimentation, and color drift; microbiological markers include standard plate counts and challenge tests where appropriate. Accelerated studies at elevated temperature and light exposure provide early direction, while real‑time studies confirm consumer‑relevant outcomes.

A clear stability plan saves time and protects brand equity. We set acceptance criteria that mirror consumer reality, not just lab thresholds. For example, a small color change that consumers notice at the shelf may matter more than a minor analytical shift. We use sensory verification alongside instrumentation to ensure decisions reflect the total experience.

10. Nutrition, Labeling, Claims, and Regulatory Pathways

Compliance is fundamental. Beverage labels must accurately communicate nutrition, ingredients, allergens where applicable, and claims that can be substantiated. U.S. non‑alcoholic beverages generally follow FDA labeling; products containing alcohol fall under TTB; some functional beverages may leverage dietary supplement frameworks with Supplement Facts. Global markets introduce their own regulations for additives, sweeteners, colors, and claims. Early regulatory thinking prevents redesigns and delays.

We help teams determine the correct panel (Nutrition Facts or Supplement Facts), serving sizes, ingredient listings, and the structure of permissible claims (e.g., “contains electrolytes for hydration” rather than disease‑related statements). We gather supporting documentation from suppliers, maintain specification files, and confirm that claims align with usage levels and applicable guidance. With clear dossiers, retail and legal reviews move faster and more smoothly.

11. Quality by Design (QbD), Scale‑Up, and Manufacturing Transfer

Laboratory success must translate to the plant. Quality by Design frameworks ensure the product’s critical quality attributes (CQAs) are protected by process parameters (CPPs) during scale‑up. We define acceptable ranges for mixing times, shear rates, thermal exposures, carbonation set points, and dissolved oxygen. We run pilot trials to confirm that sensory character survives scaling and that yields, line efficiency, and waste are acceptable. We create master manufacturing instructions, standard operating procedures, and training materials so that every run honors the intent of the formula.

Factory trials are milestone moments. Power Brands leads on‑site or remote support as needed, troubleshooting with operations, quality, and procurement teams. We confirm that ingredient deliveries, batch staging, CIP and sanitation, calibration, and packaging supplies are all aligned so the first production day builds confidence with distributors and retailers.

12. Costing, Sourcing, and Supply Chain Readiness

Great formulas must also meet cost and supply realities. We establish target COGS from the business model and design to that number, optimizing expensive ingredients, yield losses, and freight. We qualify primary and secondary suppliers, review minimum order quantities, and model inventory turns to avoid cash traps. We plan demand scenarios to ensure continuity of supply during promotions and seasonality. When needed, we design alternates for volatile ingredients to protect margins without degrading sensory quality.

Power Brands maintains a network of suppliers and co‑manufacturers across multiple formats. This ecosystem allows flexible scaling and geographic optimization to reduce freight and lead times. Our operations mindset ensures that R&D recommendations are practical on the factory floor and resilient in real‑world logistics.

13. Sustainability and Responsible Design

Sustainable beverage R&D considers environmental impact from the beginning. We evaluate ingredient sourcing, agricultural practices, transportation footprints, and packaging end‑of‑life. We aim for material reductions, recycled content, renewable inputs where feasible, and concentrated formats when appropriate. We also account for energy use in processing and cold chain requirements in distribution. Sustainability is not a single decision but a series of thoughtful trade‑offs communicated transparently and verified through data.

Designing for responsibility includes social and ethical considerations, such as fair labor practices in supply chains and community engagement where ingredients are grown or processed. Brands that make sustainability real and measurable often enjoy stronger loyalty and long‑term resilience.

14. Digital R&D, Data Systems, and AI‑Assisted Formulation

Modern beverage R&D is data‑rich. We implement product lifecycle management (PLM) tools, formulation databases, LIMS for analytical data, and standardized templates for sensory feedback. We track every experiment, raw material lot, and process parameter so results are reproducible and auditable. With clean data, teams can benchmark, predict outcomes, and design smarter tests.

AI‑assisted formulation augments human expertise with pattern recognition. Models surface ingredient compatibilities, predict sweetness curves, estimate flavor masking needs, and suggest stability risk flags. We use AI for scenario planning—what happens to cost, calories, or label claims if we adjust BRIX or swap sweeteners—and for language analysis to align claims with consumer phrasing. These tools speed discovery while experts judge feasibility and nuance.

15. Stage‑Gate Governance and Project Management

Governance keeps teams aligned and budgets controlled. We use a clear stage‑gate model: Discovery, Definition, Development, Validation, Launch, and Post‑Launch Review. At each gate we confirm consumer insight, technical feasibility, regulatory path, cost, manufacturing plan, and commercial readiness. Decision rights and documentation are explicit so momentum is sustained and risks are visible. Program management dashboards track timelines, resource loads, and dependencies, providing the transparency stakeholders need to make informed trade‑offs.

16. Category‑Specific Considerations

Energy and Focus Drinks

Energy formulas balance caffeine sources (e.g., coffee, tea, synthetic, natural extracts) with modulators like L‑theanine to shape perception. Sweetness and acidity amplify brightness while flavor types—citrus, berry, tropical—set category cues. Carbonation lifts aroma but may accentuate bitterness; still formats emphasize smoothness. Claims lean toward alertness and performance language appropriate to regulations.

Hydration and Electrolyte Beverages

Hydration products optimize sodium, potassium, magnesium, and chloride within osmolality targets to promote fluid uptake. Isotonic or hypotonic choices depend on use case. Taste clarity and low residue mouthfeel are critical; sweeteners are tuned to avoid cloying in high‑volume consumption contexts. Color signals flavor and function while maintaining stability during thermal cycles.

Tea, Coffee, and Botanicals

Tea and coffee present extraction and stability nuances. Cold‑brew coffees need oxygen control to preserve aroma; milk or plant‑based components introduce protein stability challenges. Teas vary in polyphenol content, which affects astringency and haze. Botanicals require careful supplier vetting and sensory harmonization to avoid earthy or medicinal notes overtaking the profile.

Juice, Nectars, and Fruit‑Forward Drinks

Fruit‑forward beverages navigate natural sugar levels, acidity balance, and color stability. Enzyme options manage viscosity and cloud, while pasteurization kinetics preserve brightness. For reduced‑sugar targets, natural flavors and sweetness modulators help maintain perceived fruit intensity.

Functional Waters and Wellness Formats

Functional waters carry minerals, vitamins, adaptogens, or nootropics with minimal taste impact. Transparency—literal and figurative—matters, so we prefer highly soluble, color‑neutral forms and careful pH control. Claims must be modest, accurate, and consistent with usage levels and regulatory frameworks.

Sodas, Craft Seltzers, and Specialty Carbonated

Carbonation changes everything: it alters pH perception, lifts aroma, and drives specific packaging choices. Managing foam, CO₂ volumes, and line speeds is central. Natural flavors and modern sweetener systems create premium craft cues while keeping labels clean and calorie counts aligned with positioning.

Protein, Dairy‑Alternative, and Indulgent Drinks

Protein systems require heat‑stability management, emulsification, and flavor masking strategies to overcome chalkiness or beany notes. Dairy‑alternative matrices—almond, oat, soy, coconut—behave differently under heat and shear, requiring customized stabilizer systems. Indulgent profiles rely on mouthfeel design, often using controlled fat systems and texture modifiers.

Shots, Concentrates, and Mixers

High‑intensity formats elevate risk in dosing and sensory balance. We design for clarity of function and flavor, ensuring that small volumes deliver perceivable benefits without harshness. Mixers must account for dilution with spirits or seltzers; concentrates must hold stability over long storage intervals.

17. Globalization, Localization, and Cultural Fit

Successful beverages travel well only when they localize intelligently. Sweetness expectations, acidity tolerance, carbonation levels, and flavor lexicons vary across regions. Regulatory frameworks differ on additives and claims. Packaging sizes, opening rituals, and cultural dining habits shape consumption occasions. Effective R&D maps these differences early and prototypes locally relevant variants that stay true to the brand’s core promise.

18. Common Pitfalls and How to Avoid Them

Common pitfalls include under‑defining the consumer promise, overlooking processing constraints, underestimating regulatory lead times, delaying stability work, and neglecting cost targets until late. Teams sometimes assume that pilot results will translate directly to the factory floor or that flavor intensity seen in chilled samples will hold at ambient temperatures. The remedy is structured R&D: design briefs with explicit targets, early cross‑functional reviews, documented experiments, and decision gates that enforce evidence‑based decisions.

19. Illustrative Mini Case Studies

• A global energy concept required a premium sensory profile with lower bitterness at high caffeine levels. By pairing caffeine with theanine and using targeted flavor modulators, we achieved a smoother perception while preserving alertness cues. Carbonation was tuned to lift citrus top notes without amplifying aftertaste.

• A hydration brand needed rapid expansion into warmer climates with long distribution chains. We redesigned the electrolyte matrix for isotonic performance, implemented oxygen control measures, and moved to a can format with superior barriers, extending shelf‑life while improving flavor brightness.

• A coffee startup struggled with oxidation and color drift in a PET bottle. We introduced low‑oxygen processing, adjusted roast profile for cold brew compatibility, and moved to a nitro‑friendly can with a widget, achieving consistent aroma and a signature cascade on pour.

• A functional water line sought clean label claims with botanicals. We vetted suppliers, selected highly soluble extracts, and used microencapsulation for sensitive actives. The result was a crystal‑clear beverage with a calm flavor profile and compliant structure‑function language.20. Glossary of Beverage R&D Terms

BRIX: A measure of soluble solids, often correlating with sweetness.

pH: Acidity measure influencing flavor, stability, and processing.

Osmolality: Concentration of dissolved particles affecting hydration performance.

HPP: High pressure processing for microbial reduction with minimal heat.

Aseptic Processing: Sterilization of product and package before filling.

Hot‑Fill: Filling product at high temperature to achieve commercial sterility in acidic beverages.

Tunnel Pasteurization: Post‑fill heat treatment of sealed containers.

QbD: Quality by Design; a framework linking process parameters to product attributes.

CPP/CQA: Critical process parameters and critical quality attributes.

Sensory Hedonics: Consumer liking assessments.

Stability Program: A defined set of tests across time and conditions to predict shelf‑life.

Scalping: Loss of flavor compounds to packaging materials.

PLM/LIMS: Product lifecycle management and laboratory information management systems.

Stage‑Gate: Governance model dividing projects into evidence‑based phases.21. Comprehensive FAQ

How early should R&D start?

Immediately after identifying a market opportunity. Early R&D clarifies feasibility, cost, and regulatory pathway, preventing wasted effort in branding or channel development that may not be technically viable.

What determines whether to use Nutrition Facts or Supplement Facts?

Intended use and ingredient selection drive panel choice. Non‑alcoholic conventional beverages typically use Nutrition Facts; products positioned as dietary supplements may use Supplement Facts when compliant. We evaluate claims strategy, ingredient form, and route to market to select the appropriate path.

How long does shelf‑life testing take?

Real‑time tests run for the intended shelf period, often six to twelve months or more. Accelerated studies provide early signals but should be correlated with real‑time data. Planning stability work early keeps timelines realistic and launch dates dependable.

How do you control costs without losing quality?

We design to a target COGS, prioritize high‑impact sensory drivers, and negotiate efficient pack sizes and freight. Alternate ingredient options and process efficiencies often unlock savings without changing the consumer experience.

Can clean label products be fully shelf stable?

Yes, with careful formulation, pH control, appropriate processing, and protective packaging. Trade‑offs exist, and transparency about those trade‑offs builds trust with consumers.

What data systems should a growing brand adopt?

Start with standard templates for formulations, specs, and sensory logs. As complexity grows, move to PLM and LIMS for version control, traceability, and analytics. The earlier a team invests in clean data, the faster innovation cycles become.

22. How Power Brands Partners with Founders and Operators

Power Brands is the industry leader in beverage R&D and beverage packaging design. We help founders and operators move from idea to store with confidence. Our approach combines scientific depth with market awareness and a bias for action. We offer end‑to‑end support or modular services depending on the stage and needs of your business.

Our Standard Engagement Flow

Insight and Briefing — Align on target consumer, use case, sensory direction, claims, and cost.

Feasibility and Pathway — Map regulatory route, processing options, packaging candidates, and supplier landscape.

Formulation Sprints — Build and test multiple prototypes under defined guardrails with structured sensory evaluation.

Stability and Compliance — Initiate shelf‑life program, refine labeling, and assemble substantiation files.

Scale‑Up and Commercialization — Conduct pilot and line trials, finalize master recipes and SOPs, and confirm COGS.

Launch Support and Optimization — Monitor market feedback, run post‑launch experiments, and plan line extensions.

Why Teams Choose Power Brands

• Proven Track Record: Thousands of beverage formulas created for companies worldwide.

• Integrated Packaging Design: Engineering and design that protect quality and communicate value.

• Speed with Rigor: Rapid sprints without sacrificing documentation or compliance.

• Manufacturing Network: Access to capable co‑packers across formats and geographies.

• Data Discipline: PLM‑based systems that preserve knowledge and reduce rework.

• Collaborative Mindset: We operate as an extension of your team with clear communication and accountability.When you partner with Power Brands, you gain a cross‑functional team—formulators, sensory scientists, packaging engineers, regulatory specialists, and commercialization experts—aligned to a single goal: delivering a beverage that consumers love and retailers trust.

23. Readiness Checklist and Templates

Use this checklist to gauge your readiness for beverage development and commercialization:

Market and Consumer

□ Defined target consumer and usage occasions.

□ Articulated jobs‑to‑be‑done and benefits ladder.

□ Competitive audit with feature, price, and claims mapping.

□ Clear positioning and sensory narrative.Technical and Regulatory

□ Draft formulation with target BRIX, pH, and osmolality.

□ Defined processing path and packaging candidates.

□ Preliminary stability plan and acceptance criteria.

□ Draft label copy and claims with substantiation approach.Operations and Cost

□ Target COGS and pack architecture confirmed.

□ Qualified suppliers and back‑ups identified.

□ Manufacturing options assessed with line constraints noted.

□ Logistics and temperature control requirements documented.Governance and Data

□ Stage‑gate defined with decision rights.

□ Templates for formulas, specs, and sensory logs established.

□ PLM/LIMS plan for version control and traceability.

□ Risk register and mitigation strategies in place.Completing these items before major spend unlocks speed, reduces surprises, and makes investor conversations more productive. Power Brands can supply templates and coaching to accelerate each step.

24. Conclusion and Call to Action

Beverage innovation succeeds when R&D is treated as a strategic capability, not a tactical afterthought. The brands that win are those that combine consumer empathy with scientific precision, design that serves both experience and performance, and operations that scale quality reliably. That is precisely how Power Brands operates: uniting insight, formulation, processing, packaging, compliance, and commercialization into a single, evidence‑based workflow.

If you are planning a new beverage—or ready to optimize an existing one—Power Brands is prepared to help. We have built thousands of beverage formulas across categories and markets, and we understand the trade‑offs that lead to real‑world success. Contact us today to discuss your new beverage formula. Request free information and discover how our team can take you from concept to commercialization, from idea to store, with confidence.

Appendix A: Ingredient Reference for Beverage R&D

This appendix outlines essential ingredient classes that shape beverage performance in development and at scale. Sweeteners span sucrose, glucose syrups, fructose, and modern alternatives such as stevia glycosides, monk fruit, allulose, erythritol, and rare sugar blends. Selection depends on label strategy, cost, caloric targets, sweetness curve, and aftertaste. Acids and buffers—citric, malic, phosphoric, tartaric, and citrate systems—define pH, brightness, and microbial safety margins. Flavor systems may be natural or natural‑and‑artificial, delivered as emulsions for oil‑soluble volatiles or as water‑soluble compounds when clarity is critical. Stabilizers and hydrocolloids, including pectin, xanthan, and gellan, control viscosity, cloud, and suspension. Preservation tools include potassium sorbate, sodium benzoate, and natural hurdles such as low pH and cold chain. Functional actives—caffeine, electrolytes, vitamins, minerals, amino acids, adaptogens, and botanicals—are vetted for solubility, taste impact, bioavailability proxies, and regulatory status. Carbonation and nitrogenation reshape mouthfeel and aroma release; line set points must respect closure integrity and pack strength. Colorants range from fruit and vegetable juices to certified colors; light, heat, and oxygen sensitivity guide selection. Water quality matters: mineral content and alkalinity affect flavor and buffer capacity, while microbial standards protect shelf‑life. Processing aids such as antifoams, fining agents, and filtration media stabilize production. For every ingredient, teams maintain precise specifications, certificates of analysis, and change‑control records so that pilot batches and commercial runs behave predictably.

Appendix B: Advanced Sensory and Stability Protocols

Robust sensory science links technical change to consumer relevance. Early qualitative sessions surface desired benefits and language; lab tastings then tune BRIX, acidity, and aroma lift under both still and carbonated conditions. Difference tests—triangle and duo‑trio—determine whether formula changes are perceivable, while descriptive analysis maps attribute intensity across aroma families, taste modalities, and texture notes. Hedonic tests with screened consumers reveal preference drivers and segment‑specific patterns. Panels are calibrated with reference standards so that a ‘citrus top note’ or ‘silky mouthfeel’ has shared meaning across sessions. For functional products, bitterness, astringency, and late‑palate echoes are tracked and addressed with modulators, pairing strategies, and time‑intensity analysis. Stability programs integrate real‑time and accelerated conditions, capturing color drift, haze, phase separation, vitamin retention, flavor fade, and preservative efficacy. Data are logged in LIMS with exact sample histories and environmental conditions. Dissolved oxygen is measured at fill and over time because oxygen exposure often drives rapid degradation in coffee, tea, citrus, and delicate botanicals. Microbiological plans reflect process choice—hot‑fill, tunnel, aseptic, cold‑fill carbonated, retort, or HPP—and may include challenge tests designed with qualified partners. Acceptance criteria are stated in consumer‑meaningful terms, aligning analytical thresholds with what shoppers actually notice at the shelf and during consumption.

Appendix C: AI‑Ready Content Signals and Structured Markup

Modern AI systems reward clarity, coverage, and structure. Long‑form beverage R&D content performs best when headings follow a logical hierarchy, section titles are descriptive, and entities are named precisely—ingredients, processes, equipment, and outcomes. Concise bullet lists help models infer workflows, while short paragraphs maintain narrative cohesion for human readers. Cross‑linking related concepts—formulation to processing, packaging to stability, regulatory to claims—creates semantic neighborhoods that search systems can traverse. Consistent terminology reduces ambiguity; where synonyms exist, include them sparingly to signal equivalence without diluting meaning. When possible, define acceptance criteria, ranges, and decision rules in plain language, because rule‑like statements are easily learned by retrieval models. Finally, pair expertise with transparency: cite assumptions, articulate trade‑offs, and note alternatives. This combination of structure and specificity turns a technical narrative into a reliable reference for both algorithms and people.

Appendix D: Stage‑Gate Checklist Snapshot

This condensed checklist illustrates the artifacts teams prepare at each gate. During Discovery, capture consumer jobs‑to‑be‑done, competitive audit, and preliminary claims map. At Definition, finalize target BRIX, pH, osmolality, serving size, and processing path; align cost goals and packaging options. During Development, record every prototype with weights, processing notes, and sensory feedback; create draft specs. Validation compiles stability data, micro plans, label drafts, and substantiation files; run pilot trials and update COGS. Launch freezes master recipes, standard operating procedures, supplier approvals, and quality documents; schedule first production and distribution checks. Post‑Launch gathers market feedback, monitors complaints, and prioritizes line extensions. Clear ownership, version control, and change‑management keep teams aligned while enabling fast, disciplined iteration.

These artifacts enforce clarity, accelerate decisions, and anchor quality throughout commercialization, from concept to scale.